Product Description

TurboWerks

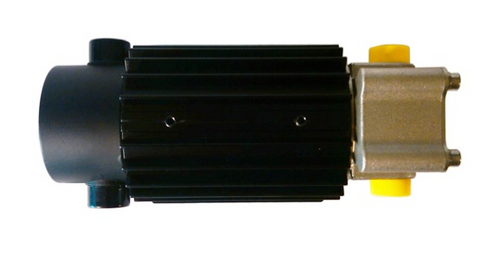

The TurboWerx Exa-Pump® is the ultimate achievement in high-temperature, high-reliability pump technology. This pump was designed from the ground up to handle the most extreme conditions found in any motor vehicle, with a special emphasis on turbocharger oil scavenging applications. Built on extremely rugged spur gear technology, there is simply no other pump that can be compared to this hi-temp, 10,000 hour continuously rated pump. Aerospace/military-grade quality finally available...and at an affordable price. The specifications and materials explain why the Exa-Pump remains #1:

• 350F (175C) Fluid Temperature

• 2-3GPM Scavenge Pump Rate depending on oil temperature/viscosity, 50+ PSI continuous as Pressure Pump

• Self-prime greater than three feet.

• Hardened Bronze Gear Pump Rotors

• 10,000 Hour Rated Dual Hybrid Ball Bearings

• 10,000 Hour Rated Over-sized Brushes

• Highest Rated Temperature (class H or higher) Insulated Copper Motor Windings

• Black Anodized Extruded Aluminum Bracket/Heatsink

• Nickel-plated Pump Head

• Stainless Steel Pump Head Fasteners

• 3/8" NPT Female Threaded Pump Head Ports

• Set of two 3/8” NPT -> AN Nickel-plated Adapters Included - Options are -6AN, -8AN, or -10AN Sizes - if size preference not specified at order time, -8AN supplied.

• High-Temperature Power Wiring

• Weatherproof Connectors

• Rubber-isolated Mounting Bracket

• Low-vibration, Quiet

• Reversible Pump Flow via Power Polarity Reversal

• Operating Current: 12 VDC version is <5A, 20A maximum. 24 VDC version is <2.5A, 10A maximum. Pump MUST be protected by circuit breaker or fuse - 12V pump 20A, 24V pump 10A. A fuse or circuit breaker will protect the pump from permanent damage in case of rotor-lock from ingesting foreign debris. When the temperature of the oil is very low, the oil’s viscosity is much greater, and the pump will consume more current until the oil warms up. The fuse or circuit breaker current value takes into account the additional current needed for pumping oil at low temperatures. As a pressure-pump, the pumps are rated min. 50PSI. Exceeding any of these ratings will void warranty. (50-75PSI operation range is possible, but not guaranteed or warranted).

Exploring the Details.

350F Fluid Temperature. No other pump comes close. All the materials used in the engineering of this pump were chosen to support extreme duty at extreme temperatures - constantly.

2-3 GPM Pump Rate. Most other pumps have a specified rating of <2GPM. The Exa-Pump's® 2-3 GPM of open-flow (0-PSI) gives the ability to easily scavenge from any turbo type or configuration, including the full flow twin turbo set-ups, or serious supplemental engine oil and/or transmission/rear-end fluid circulation through external radiators. This is also enough flow for coolant circulation in air-water intercooler systems. And finally, these pumps can generate 50 psi minimum pressure at reduced flow-rates, thus can be used in divorced turbocharger oil supply pump applications as well.

Hardened Bronze Gear Pump Rotors. Bronze spur gears create the toughest, most rugged pump head available. Gears are angle cut for quiet operation. All engine manufacturers use either gerotor or spur gears for their oil pump. Exa-Pump® uses the same ultra-reliable technology

10,000 Hour Rated Dual Ball Bearings. No other competitor's pumps use ultra-precision, ultra-high-temperature ball bearings - ALL the others use cheap, commodity, made in China 2000-2500 hour ball bearings, or worse yet, 1000 hour bushings. High temperatures drastically reduce these numbers further. This is a fundamental limit on pump life. Exa-Pump® uses a dual set of expensive 10,000-hour rated ball bearings.

10,000 Hour Rated Over-sized Brushes. Exa-Pump® engineers designed in over-size brushes to increase brush life to beyond 10,000 hours. The competitors have settled on cheap, commodity <2000 hour parts.

Black Anodized Extruded Aluminum Heatsink and Bracket. The newly designed heatsink and mounting bracket are now integrated into one very strong functional unit. The bracket/heatsink design allows the pump to be easily rotated to any position across 360 degrees for optimal port placement for any application.

Nickel-plated Pump Head. Nickel-plating serves as a tough, anti-corrosion barrier for the pump head.

Stainless Steel Pump Head Fasteners. Grade 12.9, corrosion-proof stainless steel Allen fasteners are used exclusively for the pump head assembly.

3/8" NPT F Threaded Pump Head Ports. Industry standard port sizes used.

AN Male Nickel-plated Adapters. Two AN->3/8NPT fittings included for convenience. -6AN, -8AN, or -10AN can be chosen. (If no choice specified, -8AN are provided.)

Hi-Temp Wiring. High-temperature rated wiring to support extreme environments.

Weatherproof Connectors. Standard GM WeatherPack connectors.

Rubber-isolated Mounting Bracket. Exa-pumps® use a strong steel bracket with rubber isolation mounts with an industry standard footprint for easy upgrading of existing systems.

Low-vibration, Quiet. The pump head gears are precision, angle cut. The gears are sized to reduce the motor's RPM. This results in much quieter operation, with far less vibration than the competitor's.

Power Requirement. The pumps have a wide operating range of 0% to 125% (25% over) of rated (nominal) voltage. All specifications assume a nominal Voltage. Current requirement for 12 VDC version is typically <5 Amps. Current requirement for 24 VDC version is typically <2.5 Amps. Application must use protective safety fusing or circuit breaker.

Size. The Exa-Pump® length is 6.2" long, with a 4.1" wide mounting bracket, and 3.85" diameter motor/heatsink. Mounted height is 4.1". The Exa-Pump® occupies a smaller volume than all the competition. The weight is 6 lbs.

NOTE: Do not exceed 350F rated temperature.